R+D+i

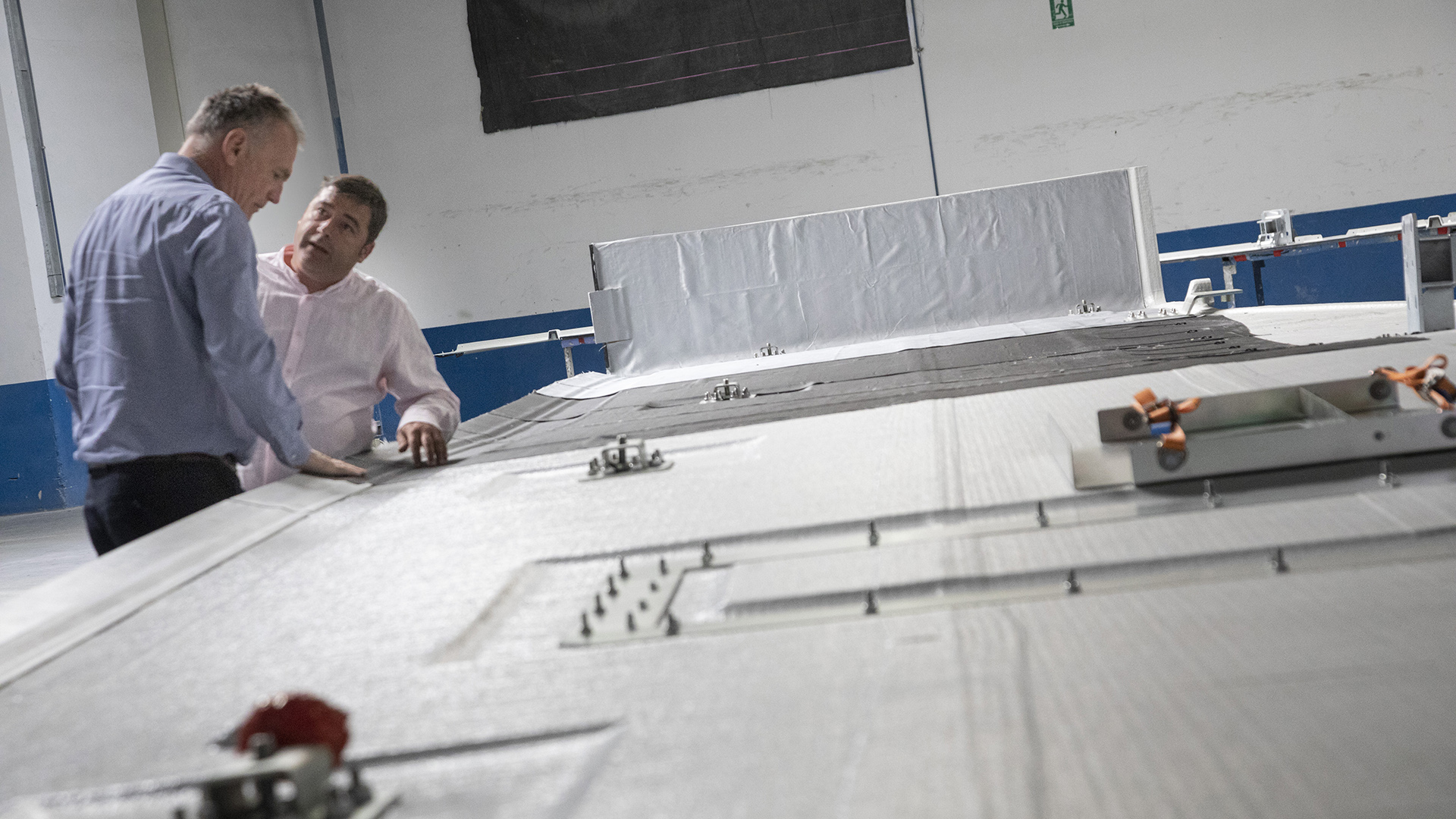

In INPRE COMPOSITES we develop new markets and sectors through R+D+i, creating new products with high added value, using new more sustainable materials and developing more optimized processes that reduce the cost during the life cycle of the product, focusing on the recyclability of new products as well as the use of existing ones, developing technologies and applications that allow the waste material to return to the production cycle.

Our lines of work are

Sustainability

Our objective is to use more sustainable technology to protect the environment, focusing on the recyclability of new products as well as the use of existing ones.

Development and implementation of new materials and processes

Take advantage of new materials existing in the market, adapting them to the needs of different sectors and develop more optimized processes that reduce the cost during the life cycle of the product.

Digitization of the industrial process

We join the digital transformation, adopting new technologies that allow us to have improved data and apply new technological solutions to improve our business model.

R+D+i Projects

Project

Nemmo

Our experience in the manufacture of large GFRP parts resulted in the start of the manufacture of blades for tidal generators in 2016. We are currently participating in the Nemmo Project, funded by the EU within the H2020 framework in collaboration with eleven other companies from five countries, with the aim of improving the design and performance of these. Our role is to research new, more resistant resins and develop the production process for innovative blades.

Holistic solution for wind turbine blade recycling

This project will develop solutions for the recycling of wind turbine blades, solutions to revalue and reuse recycled materials for the manufacture of new products for various industrial sectors. INPRE COMPOSITES will apply its know-how and experience in the manufacture of GFRP and composite materials and will guarantee the fulfillment of the objective of manufacturing products from recycled plastic materials.

Integral circular economy solution for components of wind turbines close to decommissioning

This project will develop a holistic approach to the problem of the upcoming end of life of multiple wind farms installed more than 20 years ago, in order to achieve full sustainability of the wind energy sector. INPRE COMPOSITES will develop methodologies and technologies for inspection, reconditioning and remanufacturing of the nacelle and hub casing.